What cable cross-section should I use for my installation?

Here's a recurring question that arises when your installation changes. If you change the capacity of your 230-volt or DC/DC battery charger, do you have to rewire it, too? And what happens if you increase the size of your battery bank? In this situation, the cross-section and type of cable are essential factors. An undersized cable can have serious consequences for your installation. It will create a significant voltage drop or overheating, which can lead to a fire hazard... So, it would be best to be particularly vigilant in this area. So, what cable cross-section should you use for your installation? We explain.

Reminder: what is an electrical cable?

An electric cable is a set of insulated wires grouped together in a protective sheath used to carry electricity from one point to another. Power cables can carry signals, data, or electrical energy to devices, machines, buildings, cities, or even countries via submarine cables. That said, in this article, we'll be concentrating on electrical installations.

As you will discover, cable selection is crucial to your installations' safety, efficiency, and durability. There are several criteria to consider when choosing the right cable:

- The current flowing through the cable

- Conductor cross-section

- Installation method

- The environment in which it is located

Choosing the right cable cross-section: why is it important?

If you choose a cable cross-section that's too large, your electrical installation won't be at great risk, but you'll be weighing it down unnecessarily. On the other hand, choosing a cable cross-section that's too small can expose you to significant voltage drops and can be dangerous, resulting in the worst-case scenario of a fire. Indeed, a wire with too small a cross-section will be subjected to greater stress, which can lead to overheating and melting of its insulation.

The electrical standard NF C 15-100 must, therefore, be complied with, which specifies that the choice of cable cross-section must be based on the following:

- The nature of the circuit

- Circuit breaker rating

- Cable length

What type of cable should I choose?

Before discussing cable cross-sections, it's important to remember that flexible cables are preferable to rigid ones. Smaller bending radii mean easier passage through tight spaces in your vehicle or sailboat.

Flexible cables are made of fine copper strands for great flexibility, with an outer sheath of extra-soft, insulating, self-extinguishing PVC. They are available in red (positive) and black (negative). HO7RN-F cable is readily available.

Cable cross-section calculation

To define the cable cross-section, we need to go back to school. There's a reasonably straightforward calculation formula:

S = Cable cross-section in mm². This value defines the theoretical cable cross-section in mm². Next, select the next-highest cable cross-section from the standard cable cross-sections available (1 mm², 1.5 mm², 2.5 mm², 4 mm², 6 mm², 10 mm², 16 mm², 25 mm²...).

ρ = Copper resistivity. The resistivity of a material represents its capacity to oppose the passage of a current. This value varies with temperature, and there's a complex formula for calculating it. The default value is 0.017.

L = Length of cable. This value corresponds to the distance of the cable connecting the two elements of the circuit—for example, the charger to the battery.

I = Current in Amp. This value is expressed in amperes and corresponds to the current that will flow through the cable. It generally corresponds to the rating shown on the charger (or booster).

U' = Relative voltage drop in Volts. Voltage drop occurs when a current flows through a cable and corresponds to Joule effect losses due to cable impedance. There's a complex formula for calculating it, but the default value is 3%. Therefore, the cable cross-section must be increased to compensate for this and obtain the same voltage.

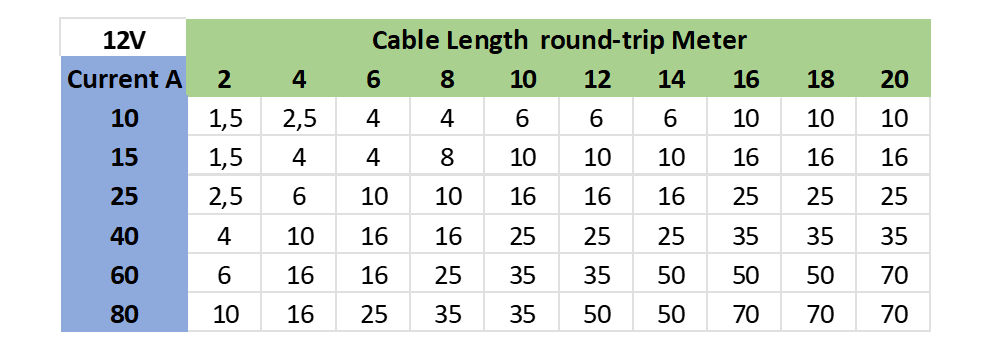

Numerous calculation rules are available on the Internet. Nevertheless, here's a table giving the recommended minimum cross-sectional area of conductors between the load and the battery for a voltage of 12.5 Volts.

Connectors: a point of vigilance

A connector provides the link between an electronic box and the cable. This connector is often the weakest link in an installation. That's why it needs special attention. There are many parameters to consider in achieving maximum reliability.

Voltage and current range, temperature resistance, traction forces, flammability, vibration resistance, accessibility for safety, etc..., are all elements to be considered. For manufacturers, the notion of wiring time and the risk of error are also taken into consideration when choosing connectors.

Dolphin® Charger has a wide range of experience in harsh environments and uses tried-and-tested industrial solutions to ensure long-term reliability for our customers. In addition, we can adapt to manufacturers' standards to harmonize our products with available cable harnesses. Would you like to find out more? Please contact us.