Did you know that battery failure is one of the most common reasons emergency generator sets fail to start?

Battery Charger Solutions for Emergency Generator sets

Introduction

Emergency/backup generator sets are installed in many fi elds such as industry, large commercial, marine, oil & gas, communication, etc. Their main purpose is to provide power when mains has failed.

The Role of Batteries

Batteries are an integral part of a generator set. The main role of emergency generator batteries is to provide power to the generator engine starter when a facility power outage occurs. Many generator service providers report the most common reason for generator failure is an expired battery.

Why install a battery charger?

A dedicated stand-alone battery charger will make sure that the starting battery is always fully charged for immediate action in case of power outage. Specifi c classifi cation society directives can also make it mandatory.

Recommended Battery Charger

An automatic smart battery charger is the preferred type of charger. An intelligent battery charger is ideal to ensure longer battery lifespan and full capacity. All our Dolphin® Chargers provides a 4 stages charging curve.

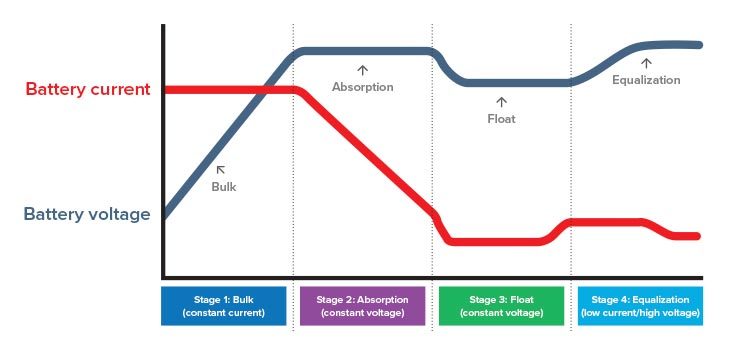

• Stage 1 (Bulk) – If the batteries are at a lower state-of-charge, usually less than 80% full, this is the fi rst stage. When in the Bulk stage mains will put as much Amperes into the batteries as possible. This is the high-speed charging stage, the higher the Amperes the faster the charge.

• Stage 2 (Absorb) – when the batteries reach the “Absorb Voltage” (this number differs depending on program settings but generally around 14.5 Volts for lead-acid batteries), the charger goes into the Absorb stage. In this stage, the batteries are kept at the voltage set by the program. The Amperes going into the batteries is lower in this stage and the batteries charge slower.

• Stage 3 (Float) – when the Absorb stage ends, the charge controller will drop the voltage to a program defi ned value and start the Float stage. This stage will kick in when the battery reaches 100% charge.

• Stage 4 (Equalization) – this stage will actually overcharge the battery, but it is only turned on periodically to override the Float stage. This is optimal for lead-acid batteries and will extend the life and performance of the battery.

Why a type-approved battery charger?

If required by specifi c classifi cation society directives a type-approved DNV-GL type approved battery charger can be installed.

To achieve DNV-GL’s approval, our DOLPHIN PRO HD+ chargers were tested by international recognised laboratories in accordance with the standard set out by IEC 60335-1 & IEC 60335-2-29, low temperature & vibration tests in accordance to SfC No. 2.4 Class A, and Humidity / Damp heat tests in accordance with SfC No. 2.4 Class A.

https://www.dolphin-charger.co...

Recommended Amperage charging rate:

We recommend a charger capacity of 10 to 20% of nominal battery capacity.

| Battery Charger | Battery Capacity Ah C20 |

| 24 Vdc 40 Amp | 200 ÷ 400 Ah |

| 24 Vdc 60 Amp | 300 ÷ 600 Ah |

| 24 Vdc 100 Amp | 500 ÷ 1000 Ah |

Communication

It is important to read the voltage or amperage directly on the battery charger itself for maintenance. Remote status and alarm information should be provided for the monitoring system.

Dolphin® Charger PRO and PRO HD+ series provide FREE contact relay for remote alarm monitoring system, canbus interface for integrated monitoring system and unique 2.5” Led Touch Display HMI.

https://www.dolphin-charger.co...