On-board DC/DC battery chargers EURO6 compliant

Introduction

As manufacturers have to comply with the new anti-pollution standards, the arrival of Euro 6 vehicles is becoming widespread. The objective is to considerably reduce emissions of polluting gases and in particular to limit nitrogen oxide (NOx), carbon monoxide (CO), unburned hydrocarbons and especially fine particles. This coincides with the arrival of intelligent alternators using regenerative braking combined with stop & start.

The role of the alternator

The alternator is still the main device that charges the battery and supplies the refrigerator while driving. The new alternators do not allow this task to be performed correctly. How many users have found themselves with a discharged domestic battery after 4 hours of driving? Indeed, the output voltage is now too low and the operating cycle unsuitable. In order to solve this problem, many manufacturers now offer «dc/dc boosters».

Why install a dc/dc booster charger?

A dc/dc charger, also called a booster, ensures that the battery will always be fully charged while driving. It is important to ensure that the booster is compatible with Euro 6 vehicles. There are several ratings available 25, 40 or 60 amps to adapt to the capacity of the battery in Ah. Some booster offer to select the charge profile in order to adapt to the battery technology (sealed lead, gel, AGM or Lithium). Finally, other products integrate a MPPT regulator allowing a PV connection.

Recommended battery charger tecnology

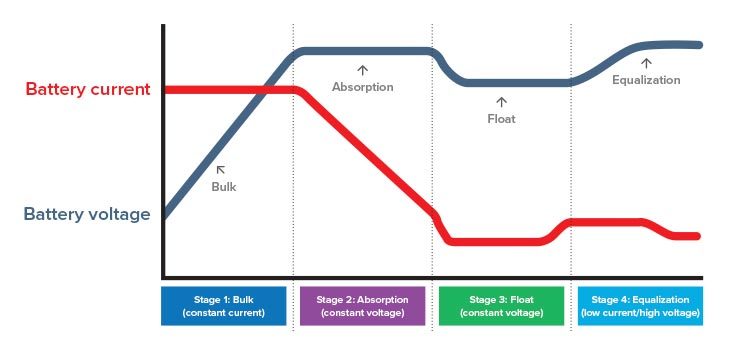

An automatic smart battery charger is the preferred type of charger. An intelligent battery charger is ideal to ensure longer battery lifespan and full capacity. All our Dolphin® Chargers provides a 4 stages charging curve.

• Stage 2 (Absorb) – when the batteries reach the “Absorb Voltage” (this number differs depending on program settings but generally around 14.5 Volts for lead-acid batteries), the charger goes into the Absorb stage. In this stage, the batteries are kept at the voltage set by the program. The Amperes going into the batteries is lower in this stage and the batteries charge slower.

• Stage 3 (Float) – when the Absorb stage ends, the charge controller will drop the voltage to a program defi ned value and start the Float stage. This stage will kick in when the battery reaches 100% charge.

• Stage 4 (Equalization) – this stage will actually overcharge the battery, but it is only turned on periodically to override the Float stage. This is optimal for lead-acid batteries and will extend the life and performance of the battery.

With or without D+ signal?

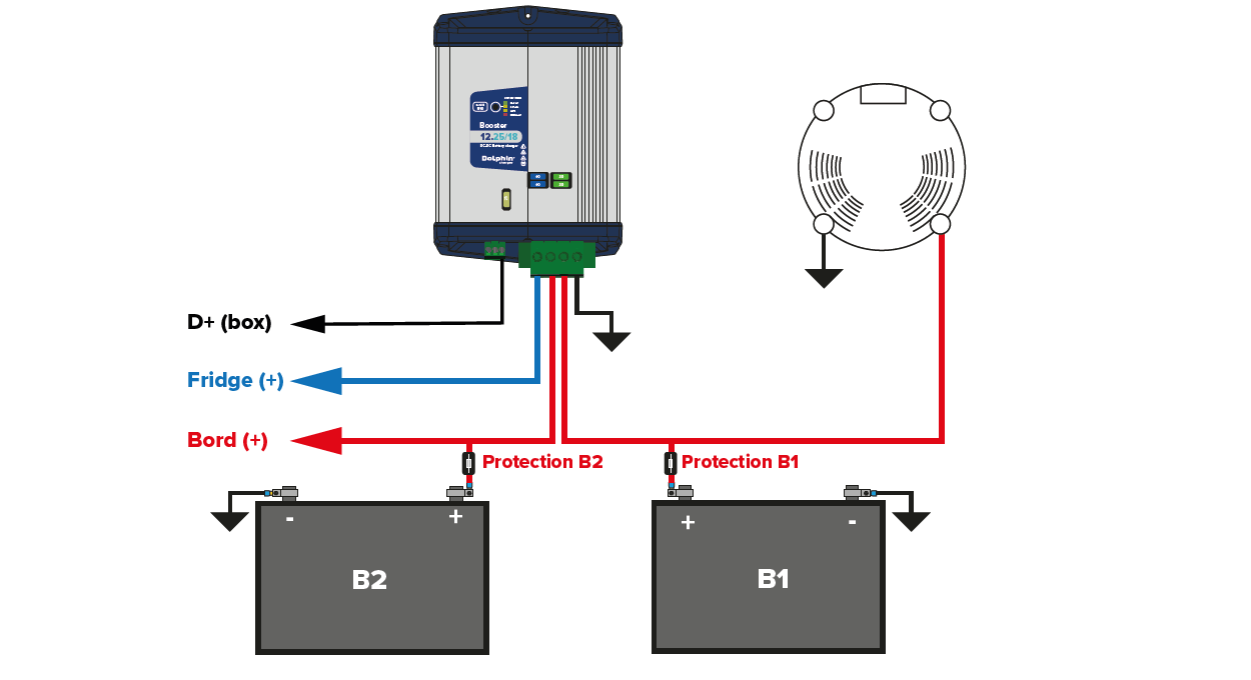

Most alternators have a D+ terminal. This terminal delivers a voltage of 12 volts when the engine is running. The D+ control of the alternator ensures that the booster only works when the engine is running. On the Dolphin® booster it is possible to select the operating mode with or without D+ control.

Why a dedicated output for the refrigerator?

Dolphin® products features a unique double output. One output is dedicated for the refrigerator. With this second output the total power available from the booster offer an extra 18 amp. In this case the 25amp booster will deliver a total output of 25a+18a. Same on 40a booster with an extra 18a for the fridge. It is possible to set this dedicated output based on the refrigerator technology (compressor or absorption).

To obtain E2-R10 approval, our 12v 25a+18a and 12v 40a+18a boosters have been tested by the UTAC CERAM laboratory in accordance with CISPR25 (2004) ISO 7637-2 (2004).

https://www.dolphin-charger.co...

Standard schematic diagram